Design and production

Railroad and railway end stops

Company benefits

The company advantages

Expert and innovative personnel: Experts, designers, managers, have been graduated from high-quality universities in Iran.

Quality and standard

Behinsazan Badie have applied ISO14001,9001,4500.

Customer satisfaction

Tehran railway company is the most important customer of Behinsazan Badie company for heavy and semi-heavy buffer stops.

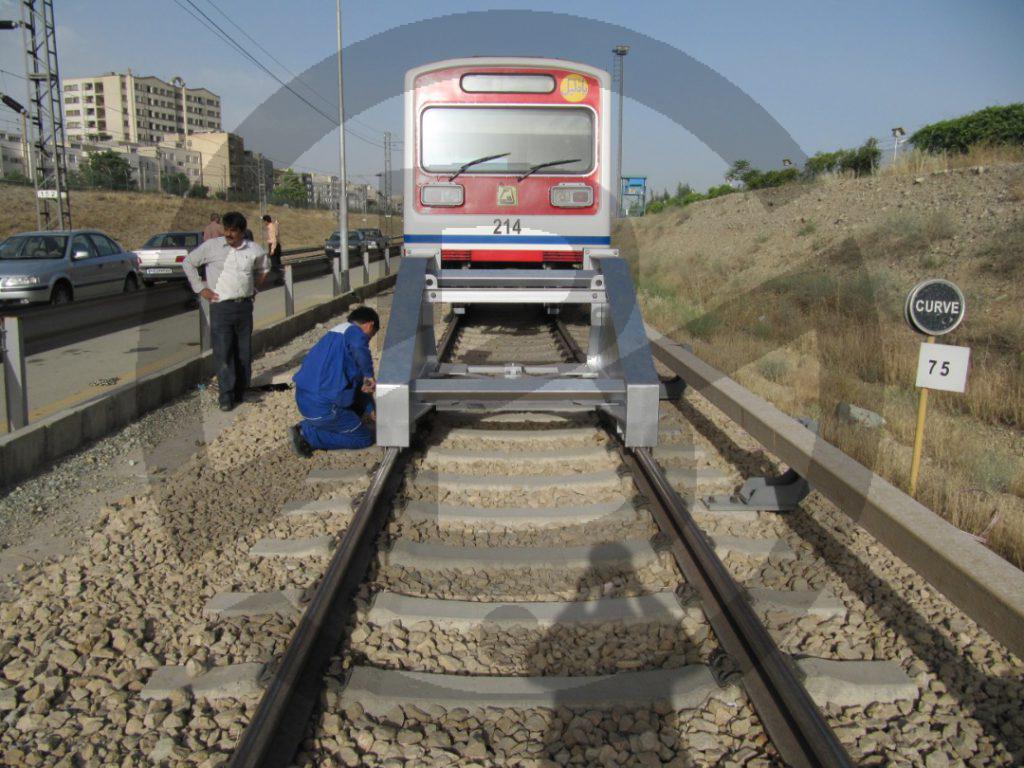

Making buffer stop in Iran

Behin Sazan Badie Private Joint Stock Company has the honor of manufacturing the first friction stoppers of Iran’s railway industry..

Introduction and application of buffer stop

In rail transport, various issues can cause accidents. These accidents can be along the railroad tracks or at the end of railroad tracks, which can cause countless financial or human losses. Railway technicians have found effective ways to reduce these accidents, especially economic losses, especially at the end of railroad tracks. One of these ways is to build equipment to keep wagons out of control at the end of the route. There are different types of these equipments and structures which are known as buffer stops among the railway industry technicians. Buffers can prevent many financial losses in terminals, depots, parking lots, and repair lines that may occur to wagons or terminals during end stops if, for some reason, a train spins out of the driver’s control and he or she is unable to do so. If the end of the railway line stops, the train will hit the end facility and possibly the walls in front of it, causing heavy financial losses to them and the wagons involved. Therefore, installing buffers at the end of rail lines is very cost-effective.

How bufferstops work

Fixed end buffers are one of the basic types of buffers that may still be used on railroad tracks due to the lack of space behind the buffers. The technology of making these buffers uses large oils and springs to absorb the kinetic energy of the train during the collision and prevent it from moving. These types of buffers, due to their stability, absorb practically all the kinetic energy and cause the train to stop at once. The advantages of making this type of buffers can be mentioned as follows. • Simplicity of design and construction • Possibility of installation in all lines and spaces • The price is right • Simplicity of maintenance steps This type of buffer is not recommended if there is a local line to dampen the vehicle speed, and the use of slippery buffers will have more benefits. Mobile buffers can prevent more damage The design of these buffers was considered when railroads expanded into cities, so equipment had to be provided to stop trains at the moment of impact and prevent them from moving further. They prevented it because the railway lines were drawn to the streets and highways and at the end of them there were office buildings and even residential buildings. The advantages of these buffers include the following: • Damping the kinetic energy of trains during a collision • Do not damage the train and its equipment • Maintaining the safety of fleet and passenger traffic • Maintain the safety of buildings and pedestrians around the end position of the lines • Easy and simple installation and adjustment after the train collides with the buffer stop

Contact Form